Water pump condition impacts water quality, energy efficiency, operational costs, and peace of mind. Regular inspections, monitoring, and smart installation can prevent catastrophic failures and protect vital infrastructure, reducing disruptions.

Water pumps are essential for residential, agricultural, and industrial systems, providing clean water, crop cultivation, and cooling equipment. Protecting investment requires long-term prevention and meticulous care. If you find yourself repeatedly facing pump disruptions or performance issues, seeking expert water pump repair services can offer both resolution and professional guidance for ongoing reliability. In this guide, we will explore in detail the underlying causes of pump failures, stress the value of consistent maintenance, review crucial installation strategies, and outline forward-thinking actions to keep your system performing efficiently for many years.

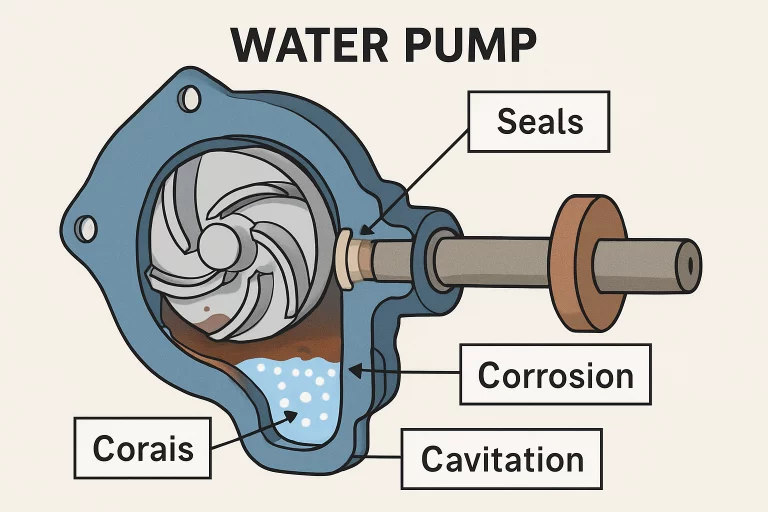

Common Causes of Water Pump Failure

Water pumps face various operational hazards that impact their efficiency and long-term durability. Seal failures, corrosion, and cavitation are common causes of failure. Seals are crucial for leak prevention and pressure maintenance, but can degrade over time due to improper installation, wear, or exposure to harsh chemicals. Corrosion can compromise metal components, leading to weakened structures and component failure. Cavitation, caused by air bubbles entering the pump, can erode impeller blades and cause noise and equipment failure. Proactive measures minimize unplanned shutdowns and protect equipment investment.

Importance of Regular Maintenance

Regular maintenance is crucial for reliable water pump operation. It involves frequent visual inspections to detect early signs of trouble, consistent bearing lubrication to prevent friction and overheating, and routine filter and strainer cleaning to prevent debris accumulation. Adhering to a strict maintenance schedule reduces emergency repairs and unexpected expenses and maximizes the pump's serviceable lifespan. Systems incorporating geothermal technology can also benefit from similar maintenance principles, ensuring long-term efficiency and performance in heating and cooling applications.

Monitoring and Early Detection

Real-time monitoring technology has revolutionized water pump management by tracking performance metrics like pressure, temperature, vibration, and flow rates. This provides early warning signs, enabling operators to intervene before minor issues escalate into major breakdowns. Vibration analysis identifies alignment issues, while continuous temperature monitoring alerts to overheating. Remote monitoring conserves manpower and provides a digital record for troubleshooting.

Proper Installation Practices

Installation is crucial for a water pump's long-term performance. It involves aligning the pump and motor, choosing seals and gaskets for pressure and fluid composition, and following the manufacturer's instructions. This ensures optimal performance from day one and reduces noise, energy consumption, and the need for intervention.

Choosing the Right Pump

Pump selection is crucial for operational reliability and cost-efficiency. It involves aligning the rated flow and pressure with the application's demands, matching materials to handle fluid characteristics, and considering environmental conditions. Engaging with a pump specialist or using detailed specification resources streamlines the process, ensuring equipment uniquely suits the application and environment.

Environmental Considerations

Environmental factors like temperature, humidity, and chemical exposure significantly impact a water pump's reliability and longevity. Install shelters, use corrosion-resistant materials, and deploy filtration systems to mitigate stress. Evaluating and addressing environmental risks at the pump's purchase and throughout its life can lead to reduced failures and more efficient performance.

Conclusion

Sustaining optimal water pump performance—and preventing disruptive breakdowns—requires a well-rounded, proactive approach that incorporates regular maintenance, detailed monitoring, careful installation, and wise equipment selection. Combined with rigorous training and environmental awareness, these strategies offer strong defenses against the unexpected. Should you notice declining performance or recurring issues, promptly reach out for trusted water pump repair support to protect your system investment. Embracing comprehensive best practices means you secure efficient water delivery, long-term reliability, and invaluable peace of mind.

No comments:

Post a Comment

I love reading and responding to comments but in order to get my reply you must ensure you are NOT a no-reply blogger. If you are, here are some quick steps to change that!

1. Go to the home page of your Blogger account.

2. Select the drop down beside your name on the top right corner and choose Blogger Profile.

3. Select Edit Profile at the top right.

4. Select the Show My Email Address box.

5. Hit Save Profile.