Key Takeaways

- Industrial pumps are essential for efficient operations across various industries.

- Implementing predictive maintenance can significantly reduce downtime and maintenance costs.

- Advancements in pump technology, such as IoT integration and AI, enhance performance and reliability.

The Critical Role of Industrial Pumps

Industrial pumps serve as the backbone of operations in sectors such as manufacturing, water treatment, and energy production. These vital components handle the movement of liquids, supporting essential processes from cooling systems to chemical production lines. When pump functionality is compromised, entire workflows can stall, resulting in operational delays and financial loss. This puts an increased emphasis on reliability and efficient maintenance of pump systems. Leading providers like Cbeuptime.com deliver advanced pump solutions designed for heavy-duty applications, ensuring consistent productivity and minimal interruption. Selecting the right industrial pump system partners and maintaining pump health are key to achieving uptime and sustained business performance.

Common Challenges in Pump Operations

Despite their central role, industrial pumps often contend with persistent operational challenges. These issues can significantly influence a plant’s efficiency and operating costs:

- Unplanned Downtime: Sudden pump breakdowns can bring entire production lines to a halt, leading to costly downtime and lost revenue.

- Energy Inefficiency: Pumps that are incorrectly sized or poorly maintained often run outside optimal ranges, which increases energy consumption and operational expenditure.

- Maintenance Issues: Traditional run-to-failure maintenance methods risk undetected problems that can result in severe system failures if left unaddressed.

Addressing these pain points is crucial, particularly as industry pressure mounts to maximize every operational dollar and reduce unscheduled interruptions.

Embracing Predictive Maintenance

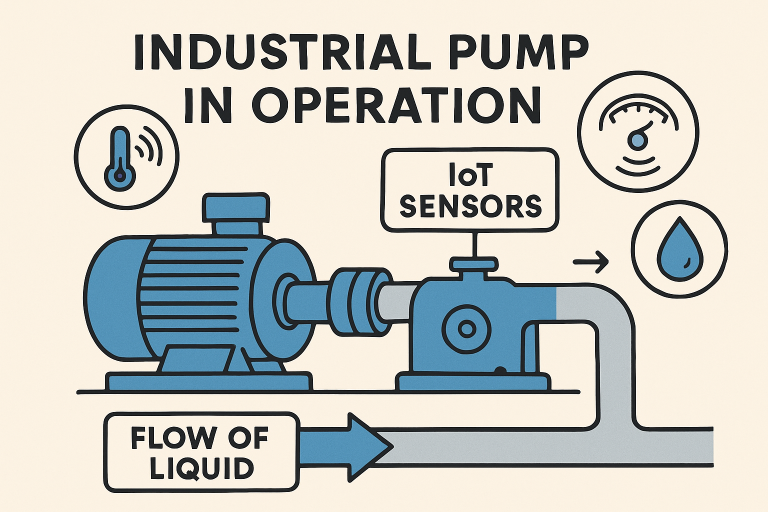

Many industries are now turning to predictive maintenance strategies to tackle the above challenges. Rather than reacting after a component breaks down, predictive maintenance uses real-time monitoring to anticipate issues in advance. Through IoT sensors and data analytics, engineers can detect subtle shifts in pump behavior—such as increased vibration or abnormal temperature spikes—that signal potential problems. This proactive approach empowers businesses to perform needed repairs before a costly failure occurs. Not only does predictive maintenance reduce unplanned downtime and related expenses, but it also extends the overall lifespan of pump equipment for a more efficient operation. Optimizing pump systems can yield significant energy savings and performance improvements across industry sectors.

Technological Advancements Enhancing Pump Performance

Recent innovations in pump technology have further strengthened reliability and sustainability:

- Smart Pumps: Integrated with IoT connectivity, these pumps autonomously track their performance, sharing critical data for remote monitoring, diagnostics, and even automated control adjustments.

- AI and Machine Learning: By analyzing large sets of performance data, AI models can predict failures with remarkable accuracy. Maintenance teams can act on these insights to preempt downtime and fine-tune processes for higher efficiency.

- Advanced Materials: New materials, such as high-grade alloys and composites, resist corrosion and abrasion better than conventional options. These choices extend lifespan, lower maintenance needs, and increase the equipment’s reliability in demanding environments.

Implementing these technological improvements enhances operational continuity and supports sustainability goals as the industry seeks to meet stricter energy and environmental standards.

Implementing Effective Pump Maintenance Strategies

Sustainable pump performance relies on a holistic maintenance approach, incorporating technology and workforce development. Plant managers and maintenance teams should follow a systematic process:

Conduct Regular Assessments: Routine evaluation of all pump systems helps identify inefficiencies and areas for improvement before they escalate.

Integrate Monitoring Technologies: Continuous monitoring through robust IoT and AI platforms delivers up-to-date health data for every critical asset.

Train Personnel: Equipping technicians with data interpretation skills and up-to-date maintenance protocols ensures effective, informed interventions.

Review and Optimize: Regularly analyze historical and live performance data to fine-tune processes and introduce equipment upgrades as needed.

These measures collectively foster a culture of proactive maintenance and operational excellence, positioning facilities for greater resilience and profitability.

Real-World Impact of Advanced Pump Solutions

The shift toward smart and predictive pump management has led to dramatic improvements in operational reliability across a range of sectors. For example, studies have shown that roughly two-thirds of industrial pumps operate below optimal efficiency, meaning there are significant untapped savings opportunities within most facilities. By routinely measuring and optimizing performance, businesses have reported millions in annual energy and maintenance savings, while reducing environmental impact and extending equipment life spans. Moreover, companies that prioritize advanced pump technologies often experience greater competitiveness and compliance with industry regulations, giving them an edge as the market continues to evolve. Investing in smarter pump systems and predictive maintenance is more than an operational decision—it's a strategic move toward future-ready resilience.

Conclusion

Industrial pumps underpin the operational continuity of countless industries. By embracing strategies such as predictive maintenance and leveraging the latest technological advancements, businesses can significantly enhance reliability, minimize costly downtime, and achieve sustainable cost savings. Staying abreast of evolving pump technologies and best practices ensures organizations maintain peak productivity and a competitive advantage in today’s dynamic industrial environment.

No comments:

Post a Comment

I love reading and responding to comments but in order to get my reply you must ensure you are NOT a no-reply blogger. If you are, here are some quick steps to change that!

1. Go to the home page of your Blogger account.

2. Select the drop down beside your name on the top right corner and choose Blogger Profile.

3. Select Edit Profile at the top right.

4. Select the Show My Email Address box.

5. Hit Save Profile.