Modern construction is undergoing a revolution with innovative techniques, materials, and smart technologies. Notably, roof truss systems have seen dramatic improvements. Designers use advanced materials and modular approaches to build more efficient, durable, and sustainable structures. These solutions boost structural integrity and architectural creativity, helping projects of all sizes adapt to modern needs.

As demands for speed, cost-effectiveness, and energy efficiency increase, truss manufacturers focus on prefabrication, digital design, and green building. This enables architects to create unique rooflines and open plans that were hard to achieve a decade ago. The following sections explore recent material advancements, fabrication methods, innovative truss designs, and trends like intelligent monitoring and eco-friendly engineering. These insights aid developers, architects, and builders in choosing resilient, forward-looking approaches. For those looking for expertly engineered solutions, wood roof trusses California professionals now offer an array of customizable systems well-suited for residential and commercial projects.

Advancements in Materials

The evolution of roof truss materials is central to their increased strength, reliability, and eco-friendliness. The industry has shifted from conventional timber toward advanced engineered wood products, such as laminated veneer lumber (LVL) and cross-laminated timber (CLT). These innovative products offer superior mechanical properties, reduced weight, and allow for longer clear spans, meaning open interiors without the need for supporting columns. Additionally, engineered wood components are produced from smaller, fast-growing trees, lessening the environmental impact of sourcing materials.

Another major leap is the adoption of lightweight metals like aluminum and advanced galvanized steel. These materials boast corrosion resistance and high load-bearing capabilities, improving longevity and reducing maintenance needs, especially in challenging climates. Such advancements in materials increase the versatility and use of truss systems, from residential homes to large commercial spaces.

Prefabrication and Automation

Prefabrication has emerged as a leading force in delivering high-quality, cost-effective roof truss systems. By fabricating trusses in a climate-controlled factory environment, manufacturers guarantee precision and consistency, minimizing on-site variances and errors. This process improves construction safety, as trusses arrive ready to install, reducing the time workers spend at heights. Automation and robotics further enhance efficiency, with automated saws, press machines, and even integrated quality assurance procedures ensuring each truss meets industry benchmarks.

The benefits are clear: project timelines shrink, waste is minimized, and overall costs drop—all without sacrificing safety or performance. As construction faces ongoing skilled labor shortages, these advances help alleviate the pressures by requiring fewer hands on site to assemble complex roof structures.

Innovative Truss Designs

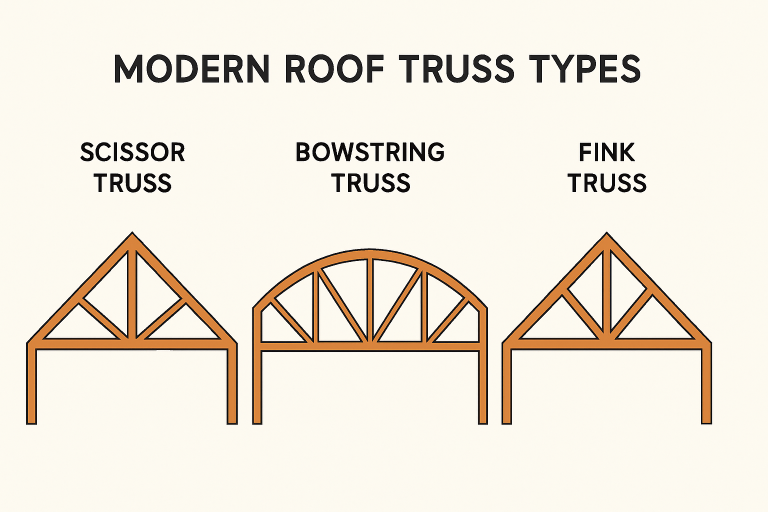

Rapid advancements in computational modeling and digital fabrication now empower architects and engineers to experiment with new and creative truss forms. While the classic king post, queen post, and Fink truss remain industry standards, contemporary spaces often leverage more expressive shapes, like scissor and bowstring trusses. Scissor trusses, for example, enable soaring vaulted ceilings and spacious, column-free interiors while structurally supporting large, open spaces. Their geometric versatility makes them a favorite in modular designs, promoting aesthetics and function.

Such innovative geometry opens doors for unique rooflines and hybrid building types, merges residential and commercial requirements, or accommodates new purposes in adaptive reuse projects. Design flexibility ensures that builders can tailor trusses precisely to the space's needs, supporting green roofing systems, clerestory windows, and even integrated solar arrays.

Sustainable Practices

With climate goals and green certifications gaining importance, sustainability in roof truss design is crucial. Using responsibly sourced materials like FSC-certified lumber and assembly-friendly designs—such as easy disassembly for reuse—helps reduce embodied carbon. Recycled steel and engineered wood trusses have long lifespans and can be repurposed. Projects now optimize truss layouts to minimize material while meeting structural needs, reducing waste.

Smart Truss Systems

Smart technology in roof truss construction is key to modern building science. Sensors inside trusses monitor load, humidity, temperature, and strain, working with management systems for instant alerts and real-time data, supporting preventative maintenance and avoiding failures. Smart trusses save energy and improve comfort by integrating with HVAC and lighting, creating efficient, adaptive environments. This leads to safer, high-performing structures with lower costs, fitting the trend of smart, connected buildings.

Conclusion

As design priorities in modern construction shift toward sustainability, speed, and flexibility, the role of the roof truss has expanded far beyond mere structural support. Advancements in materials and technology make it possible to create spaces that are as innovative as they are resilient. Techniques like prefabrication, automation, personalized truss design, and smart system integration provide developers with a toolkit for meeting evolving architectural challenges. Staying ahead of these trends ensures that projects are not only visually striking and sustainable but are built to withstand the test of time in the ever-evolving construction world.

No comments:

Post a Comment

I love reading and responding to comments but in order to get my reply you must ensure you are NOT a no-reply blogger. If you are, here are some quick steps to change that!

1. Go to the home page of your Blogger account.

2. Select the drop down beside your name on the top right corner and choose Blogger Profile.

3. Select Edit Profile at the top right.

4. Select the Show My Email Address box.

5. Hit Save Profile.