Key Takeaways

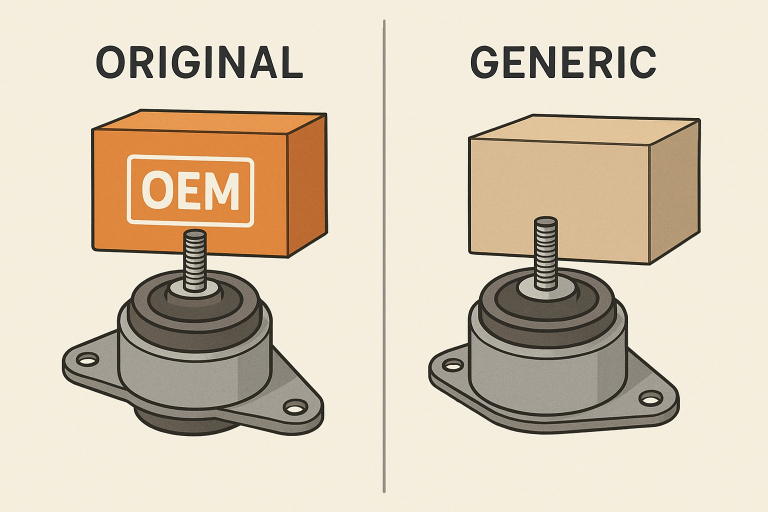

- OEM parts provide guaranteed compatibility, higher reliability, and robust manufacturer support.

- Generic parts offer cost savings but may come with risks related to quality, warranties, and proper fit.

- Knowing when to choose OEM versus generic parts can affect equipment performance, safety, and long-term costs.

Table of Contents

- What Are OEM Parts?

- Understanding Generic Parts

- Key Differences Between OEM and Generic Parts

- When to Choose OEM Over Generic Parts

- Potential Risks of Using Generic Parts

- Making an Informed Decision

- Conclusion

Whether repairing home appliances, upgrading vehicle components, or replacing elements in essential electronic devices, consumers are often faced with a critical choice: invest in Original Equipment Manufacturer (OEM) parts or opt for generic alternatives. Making the right selection can help ensure performance, longevity, and safety. For those seeking genuine replacement options, samsungparts offers access to an extensive range of OEM appliance components tailored to specific brands and models.

The distinctions between OEM and generic parts go beyond cost and branding. Understanding these differences allows users to make well-informed decisions that align with their priorities and the criticality of the equipment involved.

What Are OEM Parts?

OEM parts are components made by the company that originally manufactured the equipment or device. Each OEM part is produced to precisely match the technical and performance specifications set by the original manufacturer, ensuring that replacing a part with its OEM version maintains the device’s intended functionality, safety standards, and efficiency. According to Investopedia, OEM parts are distinguished from aftermarket alternatives by their strict adherence to original specifications. For instance, using OEM components in medical equipment is often required to comply with strict industry and regulatory standards, which ensures patient safety and reliable device operation.

Understanding Generic Parts

Generic parts, also commonly referred to as aftermarket parts, are manufactured by third-party companies independent of the original equipment maker. While designed to act as replacements for OEM parts, their specifications, materials, and build quality can vary widely. According to HowStuffWorks, this variability may affect performance, fit, and durability. Some generic parts are nearly indistinguishable from their OEM counterparts, while others could lead to issues such as improper installation, susceptibility to premature wear, or incompatibility with certain equipment features.

Key Differences Between OEM and Generic Parts

- Quality and Performance: OEM parts are engineered to meet specific durability and performance benchmarks. Generic parts, in contrast, might not undergo the same rigorous testing and can occasionally result in inconsistent performance or reliability concerns.

- Compatibility: An OEM part is guaranteed to fit the make and model of your equipment exactly as the original did. Generic parts may need modification or could fit imperfectly, potentially leading to operational challenges or even equipment damage.

- Warranty and Support: Many OEM parts are backed by warranty coverage and dedicated customer support, providing peace of mind in the event of issues that arise after installation. Generic alternatives often lack these protections, leaving buyers with limited or no recourse if a failure occurs.

- Cost Considerations: OEM parts generally come at a premium price compared to generic options. However, their longer life expectancy and superior fit may prevent costly repairs or replacements over time. Generic parts offer initial savings but could result in higher long-term expenses due to potential failures.

Another critical point is that in regulated industries—such as automotive repair—using OEM parts can help maintain a vehicle’s resale value and ensure compliance with manufacturer maintenance requirements. In critical repairs or high-value equipment, investing in OEM solutions typically offers stronger long-term value.

When to Choose OEM Over Generic Parts

Scenarios Favoring OEM Parts

- Safety-Critical Applications: Repairs that impact the safety or compliance standards of equipment, such as airbags in vehicles or components in medical devices.

- Maintaining Performance: High-performance machines and appliances where even minor deviations in fit or quality can cause issues.

- Preserving Value: When preserving the original quality, warranty, or resale value is a priority, like in newer vehicles or premium appliances.

Potential Risks of Using Generic Parts

While generic parts can be economical and sufficient for minor repairs or non-critical applications, they are not without risks. These include:

- Potential for improper fit or inferior materials, leading to system failures.

- Voidance of equipment or manufacturer warranties by installing unauthorized parts.

- Unpredictable product lifespan, which can result in more frequent replacements or higher long-term costs.

- Non-compliance with industry regulations in sectors with specific safety standards.

Making an Informed Decision

Before deciding between OEM and generic parts, evaluate the following factors:

- Assess the Part’s Importance: Is the part essential for the safe or efficient functioning of the equipment?

- Analyze Long-Term Costs: Consider not just the purchase price but the full lifecycle, including possible costs from breakdowns, downtime, or additional repairs.

- Review Warranty Coverage: Ensure you understand what is and isn’t protected by the manufacturer’s warranty if you opt for a generic replacement.

- Consult Qualified Technicians: Professional advice can clarify potential risks and help identify trustworthy sources for high-quality replacements.

Conclusion

The choice between OEM and generic parts involves balancing short-term savings with long-term performance, reliability, and support. While generic parts can be suitable for simple, non-essential repairs, OEM options provide peace of mind for critical, high-value, or safety-related applications. Evaluate the specific needs of your equipment and tap into trusted sources for authentic, manufacturer-approved replacement parts. Informed decision-making ensures you maximize the safety, value, and performance of your appliances, vehicles, and devices for years to come.

No comments:

Post a Comment

I love reading and responding to comments but in order to get my reply you must ensure you are NOT a no-reply blogger. If you are, here are some quick steps to change that!

1. Go to the home page of your Blogger account.

2. Select the drop down beside your name on the top right corner and choose Blogger Profile.

3. Select Edit Profile at the top right.

4. Select the Show My Email Address box.

5. Hit Save Profile.